|

| Home | About | Services | Tools | Case studies | Contact |

|

Introduction to tools Discrete Event Simulation Reliability Centred Maintenance Life Cycle Cost analysis | |||

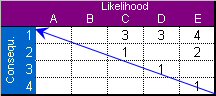

Failure Modes, Effects and Criticality AnalysisFailure Modes and Effects Analysis (FMEA) is a qualitative dependability analysis technique, which is particularly suited to the study of material, component and equipment failures and their effects. This method lends itself to analysis of items from any different technology areas: electrical, mechanical, hydraulic etc. Extending the FMEA with a Criticality Analysis, or risk ranking, the quantitative FMECA includes an assessment of the probability of occurrence of the failures.The FMEA or FMECA is a valuable tool in development programmes where a level of risk is anticipated or where reliability and maintainability reviews are required.

Evaluating Risk Click to enlarge :: Read Case study: A/S Norske Shell - Draugen :: Read Case study: A/S Norske Shell - Hasselmus

|